Enhancing Durability: The Advantages of 6307Z Bearings in Heavy-duty Environments

1. Introduction

In heavy-duty environments, the reliability and durability of bearings play a pivotal role in ensuring smooth operations and minimizing downtime. Industrial machinery subjected to high loads, extreme temperatures, and harsh conditions demands bearings capable of withstanding such challenges. Among the various types of bearings available, 6307Z bearings stand out for their exceptional performance and resilience.

6307Z bearings, also known as deep groove ball bearings, are renowned for their robustness and versatility. They are specifically designed to accommodate radial and axial loads in both directions, making them ideal for heavy-duty applications. Whether in mining equipment, construction machinery, or agricultural implements, 6307Z bearings excel in providing reliable support and smooth operation.

As we delve into the advantages of 6307Z bearings in heavy-duty environments, it becomes evident why they are the preferred choice for industries worldwide. Their ability to withstand extreme conditions while maintaining precision and performance sets them apart from conventional bearings.

2. Understanding 6307Z Bearings

Definition and Specifications of 6307Z Bearings:

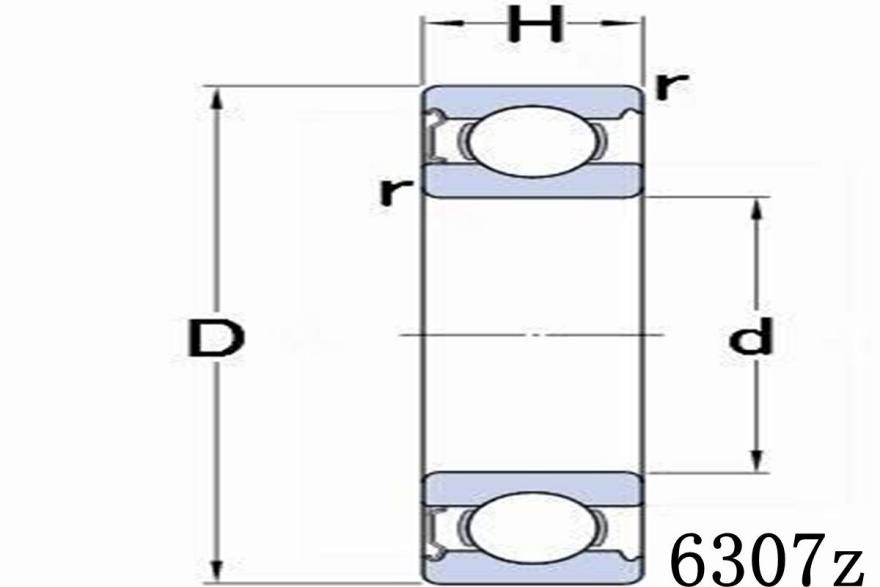

6307Z bearings are a type of deep groove ball bearings characterized by their ability to accommodate both radial and axial loads. The designation 6307Z typically indicates a single-row bearing with a shield on one side to protect against contaminants and retain lubrication. These bearings are standardized in their dimensions, with an inner diameter of 35 mm, an outer diameter of 80 mm, and a width of 21 mm, conforming to the ISO 15 standard.

Explanation of the Role of Bearings in Heavy-duty Machinery:

In heavy-duty machinery, bearings serve as crucial components responsible for supporting rotating shafts and reducing friction between moving parts. The proper functioning of bearings is essential for ensuring the smooth operation of equipment subjected to high loads and harsh operating conditions. 6307Z bearings, with their robust construction and high load-bearing capacity, excel in providing reliable support and minimizing friction, thereby contributing to the overall efficiency and longevity of heavy-duty machinery.

Comparison of 6307Z Bearings with Other Bearing Types:

When comparing 6307Z bearings with other types of bearings such as tapered roller bearings or spherical roller bearings, several key differences emerge. While tapered roller bearings are designed to handle primarily radial loads and are often used in applications with higher thrust loads, 6307Z bearings offer a more compact and lightweight solution suitable for moderate to heavy radial and axial loads. Similarly, spherical roller bearings are capable of accommodating misalignment and higher radial loads but may not be as cost-effective or space-efficient as 6307Z bearings in certain applications.

In summary, 6307Z bearings stand out for their versatility, durability, and cost-effectiveness, making them a preferred choice for heavy-duty environments where reliability and performance are paramount.

3. Advantages of 6307Z Bearings

|

High Load-Bearing Capacity |

One of the key advantages of 6307Z bearings lies in their remarkable ability to withstand heavy loads without succumbing to deformation or failure. These bearings are engineered with precision and constructed from high-quality materials, allowing them to effectively distribute and support radial and axial loads in heavy-duty machinery. Whether in mining excavators or industrial gearboxes, 6307Z bearings provide the robust support necessary to maintain smooth operations under immense pressure. |

|

Resilience to Harsh Conditions |

In heavy-duty environments characterized by extreme temperatures, moisture, and contaminants, the resilience of 6307Z bearings is unparalleled. These bearings are designed to endure adverse conditions without compromising performance or longevity. The shielded design of 6307Z bearings provides an additional layer of protection against dust, dirt, and other environmental factors, ensuring smooth operation even in the harshest of environments. |

|

Longevity and Durability |

Compared to conventional bearings, 6307Z bearings boast an extended lifespan and greater durability, resulting in reduced maintenance requirements and downtime. The superior quality of materials and meticulous manufacturing processes employed in the production of 6307Z bearings contribute to their longevity and reliability in heavy-duty applications. With proper lubrication and maintenance, these bearings can endure years of continuous operation without significant wear or degradation. |

|

Precision and Performance |

6307Z bearings are engineered for precision and optimized for performance in heavy-duty machinery. Their smooth and consistent operation minimizes friction and ensures the efficient transmission of power within industrial equipment. The precise alignment of bearing components enhances the overall performance of machinery, resulting in improved productivity and operational efficiency. |

In conclusion, the advantages of 6307Z bearings in heavy-duty environments are undeniable. From their high load-bearing capacity and resilience to harsh conditions to their longevity, durability, precision, and performance, these bearings play a crucial role in enhancing the durability and efficiency of industrial machinery.

4. Application in Heavy-duty Environments

|

Industrial Machinery |

6307Z bearings play a pivotal role in various heavy-duty industrial applications, where reliability and durability are paramount. In mining equipment, for instance, these bearings are subjected to extreme loads and harsh conditions, yet they exhibit remarkable resilience, ensuring the smooth operation of crushers, conveyors, and other machinery. Similarly, in construction machinery such as excavators and bulldozers, 6307Z bearings provide reliable support for rotating shafts, reducing friction and wear even in demanding environments. Agricultural machinery also benefits from the robustness of 6307Z bearings, with applications ranging from tractors to harvesters, where these bearings contribute to enhanced efficiency and productivity in agricultural operations. |

|

Automotive Industry |

The automotive industry relies on 6307Z bearings to withstand the rigors of rugged terrain and heavy loads in vehicles. From trucks and buses to off-road vehicles, 6307Z bearings are integral components in wheel hubs, transmissions, and steering systems. Their ability to handle both radial and axial loads ensures optimal performance and safety, even under challenging driving conditions. Moreover, in commercial vehicles used for transporting goods and materials, 6307Z bearings contribute to vehicle reliability and longevity, minimizing downtime and maintenance costs for fleet operators. |

|

Aerospace and Marine Sectors |

In aerospace and marine applications, where reliability and precision are paramount, 6307Z bearings excel in providing critical support for rotating components. Whether in aircraft engines, landing gear systems, or marine propulsion systems, these bearings ensure smooth and efficient operation, even in high-speed and high-temperature environments. The aerospace industry relies on 6307Z bearings for their lightweight construction, low friction, and high load-carrying capacity, contributing to fuel efficiency and performance. Similarly, in marine vessels ranging from cargo ships to offshore platforms, 6307Z bearings withstand corrosive seawater, vibration, and shock loads, ensuring the reliability and safety of maritime operations. |

In summary, 6307Z bearings find extensive application across a wide range of heavy-duty environments, including industrial machinery, the automotive industry, and aerospace and marine sectors, where their reliability, durability, and performance make them indispensable components for ensuring smooth and efficient operations.

5. Brand Comparison of 6307Z Bearings

Analysis of Leading Brands Offering 6307Z Bearings:

When it comes to 6307Z bearings, several renowned brands stand out in the market, each with its own reputation for quality and reliability. Among these brands, SKF, NSK, NTN, and FAG are widely recognized for their expertise in manufacturing precision bearings.

SKF, a global leader in bearing technology, is known for its extensive range of high-quality bearings designed to meet the demands of various industries. With a history dating back to 1907, SKF has established itself as a trusted supplier of 6307Z bearings, offering superior performance and durability.

NSK, another prominent player in the bearing industry, boasts a strong track record of innovation and excellence. With state-of-the-art manufacturing facilities and advanced research capabilities, NSK produces 6307Z bearings that deliver exceptional reliability and performance in heavy-duty applications.

NTN, a Japanese multinational corporation, is renowned for its comprehensive portfolio of bearings catering to diverse industrial sectors. NTN's 6307Z bearings are engineered to withstand heavy loads and harsh operating conditions, making them a preferred choice among manufacturers worldwide.

FAG, part of the Schaeffler Group, is synonymous with precision engineering and quality craftsmanship. With a focus on innovation and customer satisfaction, FAG produces 6307Z bearings that excel in terms of performance, longevity, and cost-effectiveness.

|

Brand |

Material |

Seal Type |

Load Capacity |

Speed Rating |

Price Range |

|

SKF |

High-quality steel or ceramic |

Metal or rubber seals |

High

|

High

|

High

|

|

NSK |

High-grade steel

|

Metal or rubber seals |

High

|

High

|

Moderate

|

|

FAG |

High-quality steel

|

Metal seals |

High |

High |

Moderate |

|

NTN |

High-grade steel |

Metal or rubber seals |

High |

High

|

Moderate

|

In summary, each brand offering 6307Z bearings brings its own strengths and advantages to the table, catering to the diverse needs of heavy-duty industries. Whether prioritizing performance, durability, or affordability, customers can choose from a range of options to find the ideal 6307Z bearing for their specific application.

6. Conclusion

In conclusion, 6307Z bearings offer significant advantages in heavy-duty environments, making them indispensable components in various industrial applications. With their high load-bearing capacity, resilience to harsh conditions, longevity, and precision performance, 6307Z bearings contribute to enhanced durability and efficiency in heavy machinery.

Choosing the right bearing is crucial for ensuring optimal performance and minimizing downtime in industrial operations. The superior qualities of 6307Z bearings make them the preferred choice for manufacturers seeking reliability, durability, and cost-effectiveness in their machinery.

By selecting 6307Z bearings, industries can mitigate the risks associated with equipment failure and downtime, ultimately improving productivity and profitability. It is essential for businesses to prioritize the quality and performance of bearings to maintain the integrity of their operations and achieve long-term success.

In conclusion, the advantages of 6307Z bearings in heavy-duty environments cannot be overstated. Their ability to withstand the rigors of industrial applications while maintaining precision and reliability makes them an invaluable asset for manufacturers worldwide.

7 FAQs: Common Questions About 6307z Bearings

1. What is a 6307Z bearing, and how does it differ from other types of bearings?

A 6307Z bearing is a type of deep groove ball bearing known for its ability to withstand heavy loads and harsh operating conditions. It features a single-row design with a metal shield on one side to protect against contaminants. Unlike other types of bearings, such as tapered roller bearings or spherical roller bearings, 6307Z bearings are specifically engineered for radial and axial loads in both directions, making them ideal for heavy-duty environments.

2. What are the advantages of using 6307Z bearings in heavy-duty applications?

6307Z bearings offer several advantages in heavy-duty environments, including:

- High load-bearing capacity: These bearings can withstand heavy radial and axial loads without deformation or failure.

- Resilience to harsh conditions: 6307Z bearings are resistant to extreme temperatures, moisture, and contaminants, ensuring reliable performance in challenging environments.

- Longevity and durability: Compared to conventional bearings, 6307Z bearings have an extended lifespan, reducing maintenance requirements and downtime.

- Precision and performance: These bearings contribute to smooth operation and optimal performance in heavy machinery, enhancing overall efficiency.

3. Which industries commonly use 6307Z bearings?

6307Z bearings find extensive application across various industries, including:

- Mining: Used in crushers, conveyors, and other equipment subjected to heavy loads and abrasive materials.

- Construction: Found in excavators, bulldozers, and other construction machinery operating in rugged environments.

- Agriculture: Utilized in tractors, harvesters, and other agricultural equipment for reliable performance in demanding conditions.

- Automotive: Employed in vehicles, trucks, and buses for wheel hubs, transmissions, and steering systems.

- Aerospace and marine: Used in aircraft engines, landing gear systems, and marine propulsion systems for their precision and reliability.

4. How do I choose the right brand of 6307Z bearings for my application?

When selecting a brand of 6307Z bearings, it's essential to consider factors such as product quality, performance under heavy loads, and pricing. Leading brands such as SKF, NSK, NTN, and FAG are known for their expertise in bearing manufacturing and their commitment to quality and reliability. Conducting thorough research and consulting with industry experts can help you determine the best brand for your specific application needs.

5. Are there any maintenance tips for prolonging the lifespan of 6307Z bearings?

To maximize the lifespan of 6307Z bearings, regular maintenance is essential. This includes lubrication, inspection for signs of wear or damage, and prompt replacement of worn-out bearings. Implementing a proactive maintenance schedule and adhering to manufacturer recommendations can help prevent unexpected downtime and costly repairs, ensuring the continued performance of 6307Z bearings in heavy-duty environments.

In summary, 6307Z bearings offer numerous advantages in heavy-duty environments, providing reliable support, durability, and performance in various industrial applications. By understanding their features and applications, businesses can make informed decisions when selecting bearings for their machinery, ultimately enhancing durability and efficiency in heavy-duty operations.