Precision Engineering Solutions: Maximizing Performance with 6014 Deep Groove Ball Bearing

1 Introduction

In the realm of precision engineering solutions, the 6014 deep groove ball bearing emerges as a cornerstone component, playing a pivotal role in maximizing performance across industrial settings.

The significance of precision engineering solutions cannot be overstated in industrial operations. From manufacturing plants to automotive assembly lines, the demand for high-performance components is ever-present. Among these components, bearings serve as essential elements, facilitating smooth rotation and movement within machinery. Within this landscape, the 6014 deep groove ball bearing stands out for its reliability, versatility, and ability to optimize machinery performance.

Selecting the right bearings is crucial for ensuring optimal machinery functionality and efficiency. In this regard, understanding the characteristics and applications of 6014 bearings is paramount.

2 6014 Deep Groove Ball Bearing: Overview

Structural Components and Design Specifications

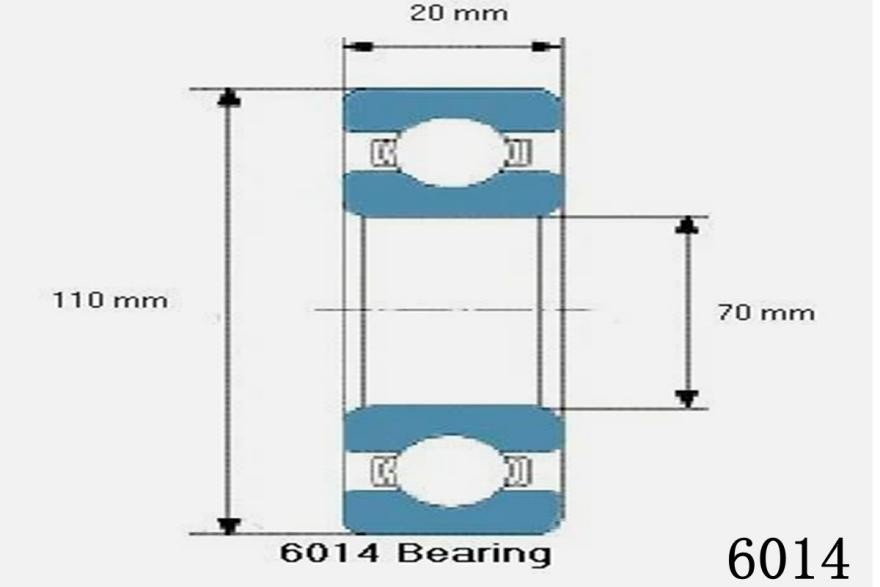

The 6014 deep groove ball bearing is meticulously engineered with precision to meet the demanding requirements of industrial machinery. Its structural composition includes an inner ring, outer ring, cage, and a complement of steel balls. These components work in harmony to facilitate smooth rotation and distribution of loads within the bearing. The design specifications of the 6014 bearing ensure optimal performance under varying operating conditions, making it a reliable choice for a wide range of applications.

Load-Bearing Capacity and Performance Characteristics

One of the distinguishing features of the 6014 bearing is its exceptional load-bearing capacity and performance characteristics. Engineered to withstand both radial and axial loads, this bearing excels in heavy-duty applications where reliability is paramount. The precision manufacturing processes employed in the production of 6014 bearings ensure consistent performance and minimal friction, resulting in smooth operation and extended service life. Whether used in conveyor systems, gearboxes, or machinery components, the 6014 bearing delivers reliable performance and optimal functionality.

Lubrication Requirements and Maintenance Guidelines

Proper lubrication is essential to maximize the performance and longevity of 6014 bearings. Adequate lubrication minimizes friction between bearing components, reducing wear and extending service intervals. It is recommended to use high-quality lubricants specifically formulated for deep groove ball bearings to ensure optimal performance. Regular maintenance practices, including lubrication replenishment and inspections, are necessary to detect any potential issues early and prevent costly downtime.

Applications Across Various Industries and Machinery Types

The versatility of 6014 bearings makes them indispensable across various industries and machinery types. From manufacturing plants to automotive assembly lines, these bearings find application in diverse industrial environments. Their ability to withstand heavy loads, high speeds, and harsh operating conditions makes them suitable for a wide range of machinery, including pumps, motors, and agricultural equipment. The reliability and performance of 6014 bearings contribute to enhanced operational efficiency and productivity across industries.

In summary, the 6014 deep groove ball bearing serves as a critical component in precision engineering solutions, maximizing performance and efficiency in industrial machinery. Its robust construction, exceptional load-bearing capacity, and versatility make it the preferred choice for applications requiring reliability and longevity. Proper maintenance and lubrication are essential to ensure optimal performance and prolong the service life of 6014 bearings.

3 Introduction to 6014 Bearing Brands

In the dynamic landscape of precision engineering solutions, the choice of bearing brands plays a critical role in determining the performance and reliability of industrial machinery. Among the multitude of options available, several major brands stand out as leaders in 6014 bearing manufacturing, each with its own unique history, reputation, and specialization in bearing production.

SKF

SKF, founded in 1907, is a renowned global leader in bearing manufacturing. With over a century of experience, SKF has established itself as a pioneer in innovation and quality within the industry. The company's dedication to research and development has resulted in numerous advancements in 6014 bearing technology, including advanced sealing solutions for contamination resistance and optimized designs for enhanced performance in demanding applications.

NSK

NSK, founded in 1916, is another prominent player in the 6014 bearing market. With a rich heritage of precision engineering, NSK has earned a reputation for excellence in bearing production. The company's commitment to technological innovation is evident in its range of 6014 bearings, which boast precision engineering for smooth operation and long service life. NSK's bearings are trusted by industries worldwide for their reliability and performance.

FAG

FAG, part of the Schaeffler Group, has been at the forefront of bearing technology since its establishment in 1883. The brand is synonymous with quality and precision, with a focus on delivering superior products that meet the highest standards of performance and durability. FAG 6014 bearings feature advanced sealing technology for enhanced contamination resistance, making them ideal for use in harsh operating environments where reliability is paramount.

NTN

NTN, founded in 1918, is a leading manufacturer of 6014 bearings known for its extensive product range and commitment to quality. The company's bearings are renowned for their reliability, versatility, and cost-effectiveness, making them a preferred choice for a wide range of industrial applications. NTN's 6014 bearings are designed to deliver optimal performance and durability, backed by the company's decades of expertise in bearing production.

Timken

Timken, founded in 1899, is a global leader in engineered bearings and power transmission products. The company's 6014 bearings are engineered for superior durability and reliability, making them suitable for the most demanding industrial applications. Timken's bearings are trusted by industries worldwide for their exceptional performance and longevity, reflecting the company's commitment to precision engineering and quality craftsmanship.

|

Brand |

Features |

Benefits |

Drawbacks |

|

SKF |

High-quality steel construction |

Excellent load-carrying capacity |

Relatively higher cost |

|

NSK |

Precision engineering for smooth operation |

Long service life |

Limited availability in some regions |

|

FAG |

Advanced sealing technology for contamination resistance |

Suitable for harsh environments |

Premium pricing |

|

NTN |

Wide range of applications |

Cost-effective option |

May require frequent maintenance |

|

Timken |

Superior durability and reliability |

Trusted brand in the industry |

Higher initial investment |

In conclusion, the choice of 6014 bearing brands is a critical decision that can significantly impact machinery performance and reliability. Each brand brings its own unique history, expertise, and innovations to the table, offering a diverse range of solutions to meet the needs of various industries. Whether it's SKF's pioneering research, NSK's precision engineering, FAG's advanced sealing technology, NTN's cost-effective solutions, or Timken's durability and reliability, industries have a plethora of options to choose from when it comes to 6014 bearings.

4 Factors Influencing Performance Optimization with 6014 Bearings

When it comes to optimizing the performance of 6014 deep groove ball bearings, several key factors come into play.

Discussion on Factors Affecting Performance

The performance of 6014 bearings can be influenced by various factors, including load conditions, operating speed, temperature, and environmental conditions. Understanding these factors is crucial for selecting the right bearing type and ensuring optimal performance in specific applications.

|

Importance of Proper Installation, Maintenance, and Lubrication |

Proper installation is paramount to the performance of 6014 bearings. Ensuring correct alignment, clearance, and preload during installation minimizes stress on the bearings and promotes smooth operation. Additionally, regular maintenance is essential to detect and address any issues early on, preventing potential damage and extending the bearing's lifespan. Lubrication also plays a vital role in reducing friction and wear, thus enhancing the performance and longevity of 6014 bearings. Using the appropriate lubricant and adhering to recommended lubrication intervals are critical for optimal bearing operation.

|

|

Strategies for Enhancing Performance and Prolonging Lifespan

|

To optimize the performance of 6014 bearings and prolong their lifespan, several strategies can be employed. Implementing condition monitoring techniques, such as vibration analysis and thermography, enables early detection of potential problems, allowing for timely maintenance interventions. Additionally, selecting bearings with higher load-carrying capacity and improved sealing options can enhance performance in demanding applications. Furthermore, upgrading to advanced bearing materials and coatings can increase resistance to wear and corrosion, further extending the bearing's service life.

|

In conclusion, optimizing the performance of 6014 deep groove ball bearings requires careful consideration of various factors, including proper installation, maintenance, and lubrication practices. By implementing strategies aimed at enhancing performance and prolonging lifespan, industries can maximize the efficiency, reliability, and longevity of their machinery systems, ultimately leading to improved operational performance and reduced downtime.

5 Conclusion

In conclusion, precision engineering solutions play a pivotal role in optimizing machinery performance, and 6014 deep groove ball bearings stand at the forefront of this endeavor. Throughout this article, we have explored the significance of precision engineering in industrial settings, highlighting the critical role that 6014 bearings play in maximizing machinery performance.

Precision engineering solutions encompass a range of practices and technologies aimed at achieving optimal efficiency, reliability, and precision in industrial machinery. From design and manufacturing processes to maintenance and optimization strategies, precision engineering permeates every aspect of modern industrial operations.

Central to the success of precision engineering is the selection of the right components, and 6014 bearings exemplify this principle. With their robust construction, high-performance characteristics, and versatility, 6014 bearings are indispensable assets in various industrial applications. They facilitate smooth operation, withstand heavy loads, and contribute to overall machinery efficiency and productivity.

As we move forward, it is imperative for industries to embrace advanced engineering solutions, including the adoption of cutting-edge bearing technologies like the 6014 deep groove ball bearing. By investing in precision engineering and leveraging the capabilities of high-quality bearings, businesses can achieve significant improvements in operational performance, reduce downtime, and enhance overall competitiveness.

Therefore, I urge stakeholders across industries to prioritize precision engineering solutions and recognize the pivotal role that 6014 bearings play in maximizing machinery performance. By embracing advanced engineering practices and investing in quality components, we can propel industrial operations to new heights of efficiency, productivity, and success.

6 FAQs: Common Questions About 6014 Bearing

As we delve into the realm of precision engineering solutions and the pivotal role of 6014 deep groove ball bearings, it's essential to address some common questions that often arise regarding these crucial components. Below are some frequently asked questions about 6014 bearings:

1. What is a 6014 bearing?

- A 6014 bearing is a type of deep groove ball bearing characterized by its ability to accommodate radial and axial loads in both directions. It features a deep groove design, making it suitable for high-speed and high-precision applications.

2. What are the structural components of a 6014 bearing?

- A 6014 bearing typically consists of inner and outer rings, steel balls, a cage, and seals or shields. These components work together to facilitate smooth rotation and minimize friction, thereby optimizing machinery performance.

3. What are the applications of 6014 bearings?

- 6014 bearings find widespread applications across various industries, including automotive, aerospace, industrial machinery, and more. They are used in gearboxes, electric motors, pumps, and other rotating equipment where precision and reliability are paramount.

4. What are the key features of 6014 bearings?

- 6014 bearings are known for their high load-carrying capacity, low friction, and long service life. They are designed to operate efficiently in diverse operating conditions, including high temperatures and corrosive environments.

5. How do I select the right 6014 bearing for my application?

- When selecting a 6014 bearing, factors such as load requirements, operating speed, temperature, and environmental conditions should be considered. Consulting with bearing experts and adhering to manufacturer specifications can help ensure the optimal selection.

6. What maintenance is required for 6014 bearings?

- Proper maintenance is essential to prolong the lifespan of 6014 bearings. This includes regular lubrication, inspection for signs of wear or damage, and replacement of worn components as needed. Following manufacturer guidelines and best practices is crucial for optimal performance.

7. Are there any common issues or challenges associated with 6014 bearings?

- While 6014 bearings are known for their reliability, common issues such as contamination, improper installation, and overloading can affect performance. Addressing these issues promptly and implementing preventive maintenance measures can mitigate potential problems.

8. What are the benefits of using high-quality 6014 bearings?

- High-quality 6014 bearings offer numerous benefits, including improved machinery performance, reduced downtime, lower maintenance costs, and enhanced operational efficiency. Investing in quality bearings can yield significant long-term savings and productivity gains.

In conclusion, 6014 bearings are integral components in precision engineering solutions, playing a vital role in maximizing machinery performance across various industries. By addressing common questions and concerns about 6014 bearings, stakeholders can make informed decisions and optimize their applications for success.