Unveiling the Efficiency: Exploring the Versatility of 6206 RS Deep Groove Ball Bearings

Introduction

In the realm of mechanical engineering, deep groove ball bearings stand out as vital components, facilitating smooth motion and reducing friction in a wide array of machinery and equipment.Explores the importance of deep groove ball bearings, with a special focus on the versatility and efficiency of the 6206 RS variant.

Deep groove ball bearings, as the name suggests, feature deep raceway grooves, enabling them to accommodate radial and axial loads in both directions. Their design allows for high-speed operation while maintaining low noise and vibration levels, making them indispensable in numerous industrial applications.

Structure and Components

Deep groove ball bearings, such as the 6206 RS variant, boast a sophisticated design comprising several essential components that synergistically work together to ensure optimal performance and efficiency.

|

Outer Ring |

The outer ring, often referred to as the outer race, serves as the primary structural support for the bearing. Constructed from durable materials like steel or stainless steel, the outer ring provides rigidity and stability to the bearing assembly, allowing it to withstand radial loads while maintaining dimensional integrity. |

|

Inner Ring |

Opposite the outer ring lies the inner ring, also known as the inner race. Similar to the outer ring, the inner ring is crafted from robust materials and designed to fit snugly onto the shaft. Its role is to support and guide the rolling elements, facilitating smooth rotation and minimizing frictional losses. |

|

Rolling Elements |

Nestled between the inner and outer rings are the rolling elements, typically ball bearings in deep groove ball bearings. These precision-engineered spheres distribute the load evenly across the bearing's raceways, enabling it to withstand both radial and axial forces. The smooth, low-friction motion of the rolling elements is critical to the overall efficiency of the bearing. |

|

Cage |

To maintain proper spacing and alignment of the rolling elements, deep groove ball bearings employ a cage, also known as a separator. The cage ensures that the balls remain evenly spaced and do not come into contact with each other, reducing the risk of friction and wear. Additionally, the cage allows for efficient lubricant distribution throughout the bearing assembly. |

|

Seals or Shields |

In the case of the 6206 RS deep groove ball bearing, the "RS" designation signifies the presence of rubber seals on one side of the bearing. These seals act as protective barriers, preventing contaminants such as dust and moisture from infiltrating the bearing and compromising its performance. Alternatively, shields may be used to provide similar protection while allowing for slightly higher speeds. |

Importance of Components:

Each component of the 6206 RS deep groove ball bearing plays a crucial role in its overall efficiency and performance. From the structural integrity provided by the outer and inner rings to the smooth motion facilitated by the rolling elements and cage, every aspect contributes to the bearing's ability to operate reliably and efficiently in various applications. Understanding the intricacies of these components is essential for appreciating the versatility and effectiveness of 6206 RS bearings in diverse mechanical systems.

Applications and Versatility

Deep groove ball bearings, particularly the 6206 RS variant, exhibit remarkable versatility and find extensive applications across various industries and mechanical systems. we delve into the diverse environments and operating conditions where these bearings prove indispensable:

Automotive Industry:

In the automotive sector, 6206 RS deep groove ball bearings are commonly employed in vital components such as wheel hubs, transmissions, and electric motors. Their ability to withstand high radial loads and moderate axial loads makes them ideal for supporting rotating shafts while ensuring smooth and efficient vehicle operation.

Industrial Machinery:

In industrial machinery, 6206 RS bearings play a crucial role in a multitude of applications, including conveyor systems, pumps, fans, and gearboxes. Their robust construction and reliable performance make them suitable for heavy-duty operations, where they endure varying loads and speeds with minimal maintenance requirements.

Agricultural Equipment:

Within the agricultural sector, 6206 RS deep groove ball bearings find utility in a wide array of equipment, ranging from tractors and harvesters to irrigation systems and grain augers. Their ability to operate efficiently in harsh outdoor environments, including exposure to dirt, dust, and moisture, makes them indispensable for maintaining productivity in agricultural operations.

Electric Motors and Power Tools:

In electric motors and power tools, 6206 RS bearings serve as essential components, providing support and facilitating rotational motion. Whether in household appliances like washing machines and vacuum cleaners or power tools such as drills and saws, these bearings contribute to the overall performance and longevity of the equipment.

Aerospace and Defense:

Even in the aerospace and defense industries, where precision and reliability are paramount, 6206 RS bearings find niche applications. From aircraft landing gear and engine components to military vehicles and missile systems, these bearings deliver exceptional performance under demanding conditions, ensuring the safety and functionality of critical machinery.

Conclusion:

|

Brand |

Model |

Outer Diameter (mm) |

Inner Diameter (mm) |

Width (mm) |

Dynamic Load Rating (kN) |

Static Load Rating (kN) |

Max. Speed (rpm) |

Seal Type |

Cage Material |

|

SKF |

6014 |

110 |

70 |

20 |

39.7 |

31.5 |

10,000 |

Rubber |

Steel |

|

FAG |

6014 |

110 |

70 |

20 |

41.5 |

33.5 |

9,500 |

Metal |

Brass |

|

NSK |

6014 |

110 |

70 |

20 |

41.5 |

33.5 |

9,000 |

Rubber |

Steel |

|

NTN |

6014 |

110 |

70 |

20 |

41.5 |

33.5 |

9,500 |

Rubber |

Steel |

|

Timken |

6014 |

110 |

70 |

20 |

42.5 |

34.5 |

9,000 |

Metal |

Brass |

The versatility of 6206 RS deep groove ball bearings extends across a broad spectrum of industries and applications, from automotive and industrial machinery to agriculture, electric appliances, and aerospace. Their ability to operate effectively in diverse environments, coupled with their reliability and durability, underscores their significance as indispensable components in modern engineering and technology.

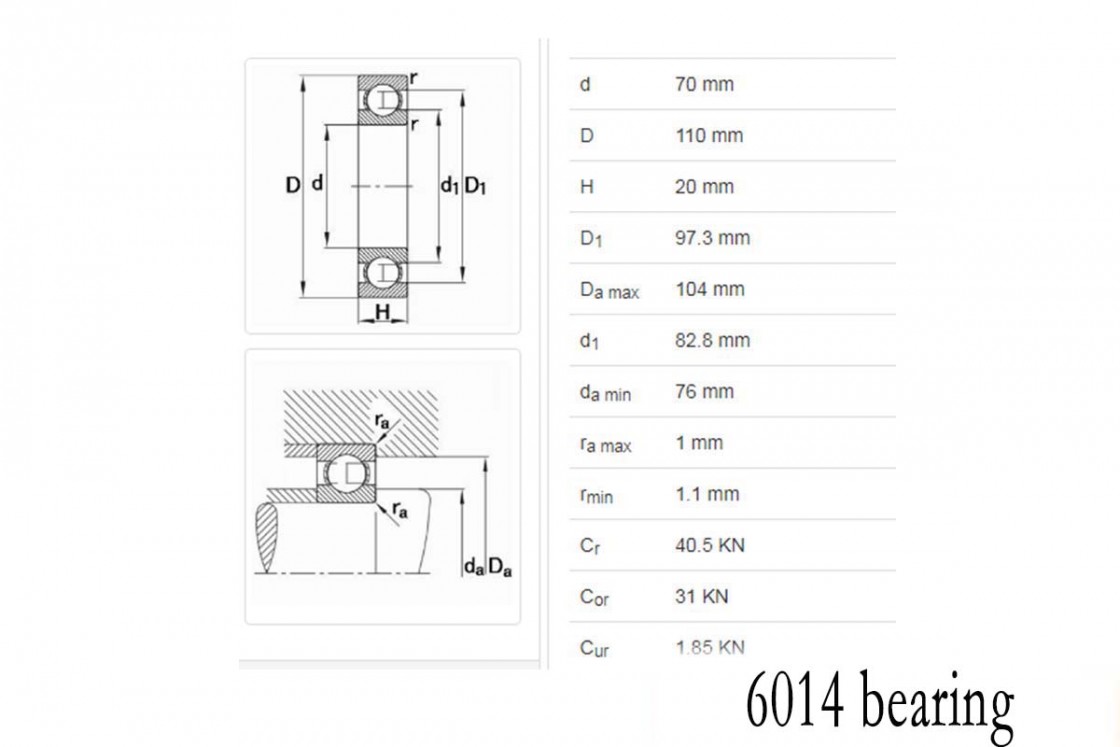

This comparison table provides key specifications of 6014 deep groove ball bearings from various brands, including SKF, FAG, NSK, NTN, and Timken. The table includes details such as model, outer diameter, inner diameter, width, dynamic load rating, static load rating, maximum speed, seal type, and cage material. It serves as a useful reference for engineers and buyers when selecting the most suitable bearing for their specific applications.

Performance Metrics

Deep groove ball bearings, particularly the 6206 RS variant, are characterized by various performance metrics that determine their efficiency and effectiveness in different applications. Below, we explore the key performance metrics associated with these bearings and the factors influencing their performance:

Load Capacity:

One of the fundamental performance metrics of 6206 RS deep groove ball bearings is their load capacity, which refers to the maximum load they can withstand without experiencing permanent deformation or failure. These bearings are designed to accommodate both radial and axial loads, making them versatile for applications where forces act from different directions.

Speed Ratings:

Speed ratings are crucial performance metrics that indicate the maximum rotational speed at which a bearing can operate reliably without excessive heat generation or premature wear. 6206 RS bearings are engineered to deliver high-speed performance, enabling efficient operation in applications with varying rotational speeds, such as machinery and automotive components.

Precision:

Precision is another essential performance metric for deep groove ball bearings, especially in applications where tight tolerances and accurate positioning are critical. 6206 RS bearings are manufactured with precision components and advanced machining techniques to ensure consistent and uniform performance, contributing to the overall efficiency and reliability of the equipment they support.

Lubrication:

Proper lubrication is vital for maintaining the performance and longevity of 6206 RS bearings. Adequate lubrication reduces friction and wear between the bearing components, ensuring smooth operation and preventing premature failure. Different lubrication methods, such as grease and oil lubrication, are employed based on the application requirements and operating conditions.

Sealing and Contamination Resistance:

6206 RS bearings are equipped with seals or shields to protect the internal components from contaminants such as dust, dirt, and moisture. These seals enhance the bearing's resistance to contamination, prolonging its service life and preserving its performance even in harsh environments.

Conclusion:

Performance metrics play a crucial role in evaluating the efficiency and reliability of 6206 RS deep groove ball bearings. By understanding and optimizing factors such as load capacity, speed ratings, precision, lubrication, and sealing, engineers and designers can maximize the performance and longevity of these bearings in various industrial and mechanical applications.

Maintenance and Care Guidelines

Deep groove ball bearings, such as the 6014 variant, play a critical role in the smooth operation of various industrial applications. To ensure their longevity and optimal performance, it's essential to adhere to proper maintenance and care guidelines. Comprehensive steps for effective maintenance and care of 6014 deep groove ball bearings.

Regular Inspections

Regular inspections are fundamental to identifying potential issues early on and preventing unexpected failures. Inspect the bearing housing, seals, and surrounding components for signs of wear, corrosion, or damage. Check for abnormal noises or vibrations during operation, which may indicate misalignment or bearing fatigue.

Lubrication Routines

Proper lubrication is paramount for reducing friction, minimizing wear, and dissipating heat within the bearing assembly. Follow the manufacturer's recommendations regarding lubricant type, quantity, and application intervals. Ensure that the lubricant is compatible with the operating conditions and environmental factors, such as temperature and humidity.

Cleaning Procedures

Periodically clean the bearing housing and surrounding areas to remove contaminants, dirt, and debris that could impair performance. Use mild solvents or cleaning agents and avoid harsh chemicals that may degrade the seals or bearing surfaces. Thoroughly dry the components before applying fresh lubricant.

Temperature and Environmental Considerations

Monitor the operating temperature of the bearing assembly to prevent overheating, which can accelerate wear and reduce lifespan. Ensure proper ventilation and cooling mechanisms in high-temperature environments. Protect the bearings from exposure to moisture, dust, and corrosive substances by implementing appropriate seals and covers.

Handling and Storage Practices

Exercise caution when handling and installing 6014 deep groove ball bearings to avoid mechanical damage or contamination. Store bearings in a clean, dry environment away from direct sunlight and extreme temperatures. Use appropriate handling equipment, such as lifting slings or cranes, to prevent mishandling and ensure safety.

Monitoring and Replacement

Regularly monitor the condition and performance of 6014 bearings through vibration analysis, temperature monitoring, and periodic inspections. Keep detailed records of maintenance activities and observations to identify trends or potential issues over time. When signs of wear or deterioration become apparent, promptly schedule bearing replacement to prevent costly downtime and equipment damage.

By following these maintenance and care guidelines diligently, operators can maximize the efficiency, reliability, and lifespan of 6014 deep groove ball bearings, thereby optimizing overall system performance and minimizing operational disruptions.

Future Trends and Innovations

In the realm of deep groove ball bearings, including the versatile 6014 variant, ongoing advancements and innovations continually shape the landscape of industrial machinery and equipment.Future trends and potential innovations in deep groove ball bearing technology, with a special focus on how these developments can increase the efficiency and versatility of bearings such as model 6014.

|

Trend |

Description |

|

Nanotechnology Integration |

One emerging trend in bearing technology involves the integration of nanomaterials to enhance performance and longevity. Nanotechnology allows for the creation of ultra-smooth bearing surfaces, reducing friction and wear while improving load capacity and durability. |

|

IoT and Predictive Maintenance |

The Internet of Things (IoT) has revolutionized industrial maintenance practices, enabling real-time monitoring and predictive maintenance of critical equipment. Smart bearings equipped with sensors and wireless connectivity can provide valuable insights into bearing health, temperature, vibration levels, and lubrication status. |

|

Advanced Lubrication Techniques |

Lubrication plays a vital role in ensuring the smooth operation and longevity of deep groove ball bearings. Future innovations in lubrication technology focus on developing advanced lubricants with superior performance characteristics, such as enhanced thermal stability, oxidation resistance, and compatibility with varying operating conditions. |

|

3D Printing and Customization |

The advent of 3D printing has opened new avenues for customization and rapid prototyping in bearing manufacturing. Manufacturers can design and produce bespoke bearing components tailored to specific applications, optimizing geometries, materials, and performance parameters. |

|

Sustainability and Environmental Responsibility |

As environmental concerns continue to drive industry practices, bearing manufacturers are increasingly focused on sustainability and eco-friendly solutions. Future innovations aim to reduce the environmental impact of bearing production processes, minimize energy consumption, and enhance recyclability. Eco-friendly lubricants, biodegradable materials, and energy-efficient manufacturing techniques contribute to a more sustainable future for deep groove ball bearings, including the 6014 variant. |

By staying abreast of these future trends and innovations in deep groove ball bearing technology, stakeholders can harness the potential to enhance the efficiency, reliability, and sustainability of industrial machinery and equipment, ultimately driving progress and innovation across various sectors.

FAQs: Common Questions About 6014 Deep Groove Ball Bearings

What is a 6014 Deep Groove Ball Bearing?

A: A 6014 deep groove ball bearing is a type of rolling-element bearing characterized by its deep raceway grooves and uninterrupted raceway rings. These bearings are commonly used in various applications due to their versatility and ability to accommodate radial and axial loads.

What are the Key Features of 6014 Bearings?

A: The key features of 6014 bearings include their deep groove design, which facilitates high-speed operation and efficient load distribution. They also typically have steel or ceramic construction for durability and resistance to corrosion.

What are the Dimensions of a 6014 Bearing?

A: The dimensions of a standard 6014 deep groove ball bearing are typically as follows: inner diameter (bore) of 70 mm, outer diameter of 110 mm, and width of 20 mm. However, variations in dimensions may exist depending on the specific manufacturer and design.

What Applications are Suitable for 6014 Bearings?

A: 6014 bearings find applications in a wide range of industries, including automotive, industrial machinery, agricultural equipment, and appliances. They are commonly used in electric motors, pumps, gearboxes, and conveyor systems, among others, where high-speed operation and efficient load handling are required.

How Do I Properly Install and Maintain 6014 Bearings?

A: Proper installation and maintenance are essential for maximizing the performance and longevity of 6014 bearings. During installation, ensure accurate alignment and proper mounting to prevent misalignment and premature wear. Regular maintenance activities include lubrication, inspection for wear or damage, and monitoring of operating conditions.

What Factors Should I Consider When Selecting 6014 Bearings?

A: When selecting 6014 bearings for a specific application, consider factors such as load capacity, operating speed, temperature range, and environmental conditions. Additionally, evaluate the bearing's material, lubrication requirements, and sealing options to ensure compatibility with the intended use.

Where Can I Find Reliable Suppliers of 6014 Deep Groove Ball Bearings?

A: Reliable suppliers of 6014 bearings can be found through various channels, including authorized distributors, online marketplaces, and direct manufacturers. It is essential to choose reputable suppliers with a proven track record of quality products and reliable customer service to ensure the procurement of genuine and high-performance bearings.