6206rs Unveiled: Navigating the Realm of High-Performance Bearings Introduction

In the intricate machinery that powers various industries, the role of high-performance bearings is paramount. These components serve as the unsung heroes, ensuring the seamless operation of equipment and machinery. Among the array of high-performance bearings, one stands out – the 6206RS 30x62x16 Sealed Ball Bearings. delving into their dimensions and sealed design that contribute to their exceptional performance.

it's crucial to comprehend the broader significance of high-performance bearings. These components form the backbone of industries, from manufacturing to automotive, ensuring the smooth rotation and functionality of countless machines. Now, our focus sharpens on a specific variant – the 6206RS bearings – as we navigate through the intricacies of their design and applications in various sectors.

Exploring 6206RS Bearings

In the heart of high-performance ball bearings, the 6206RS stands as a beacon of precision and reliability. Understand the complexity of its specifications and design. 6206RS bearings become the technical level of the cornerstone of the field of advanced machinery and equipment.

Specifications of 6206RS Bearings

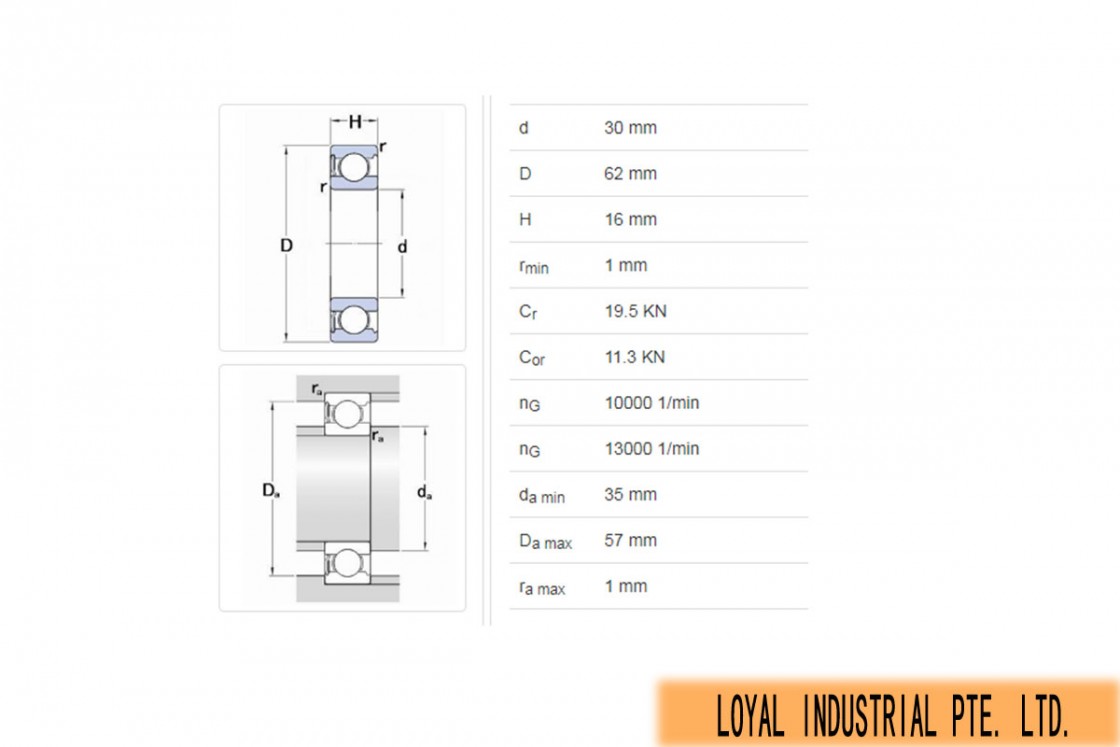

Dimensions: 30x62x16

The numerical nomenclature of 30x62x16 encapsulates the fundamental dimensions of these bearings. The first two digits, 30 and 62, represent the bore diameter and outer diameter, respectively. A bore diameter of 30mm ensures compatibility with a range of shaft sizes, offering versatility in application. Meanwhile, the 62mm outer diameter contributes to the bearings' stability and load-bearing capacity.

The third digit, 16, signifies the width of the bearing. This dimension plays a critical role in determining the bearing's ability to withstand axial loads. The balanced ratio of these dimensions in 6206RS bearings ensures optimal performance across diverse operational conditions.

Sealed Design

One of the distinguishing features of 6206RS bearings lies in their sealed design. The incorporation of seals serves as a protective shield, preventing contaminants from entering the bearing and preserving the internal lubrication. This sealed structure enhances the bearing's lifespan and operational efficiency, making it a preferred choice in applications where cleanliness and reliability are paramount.

Significance in High-Performance Applications

6206RS bearings find their niche in the realm of high-performance applications, thanks to their meticulously engineered design. The bearings' ability to withstand high speeds and loads positions them as essential components in various industries, including automotive, manufacturing, and robotics.

Applications Across Industries

In the intricate world of machinery and equipment, the 6206RS 30x62x16 Sealed Ball Bearings stand as exemplars of high-performance engineering, elevating standards across various industries.

Versatility in Automotive Systems

6206RS bearings play a pivotal role in the automotive industry, where precision and reliability are paramount. From supporting the smooth rotation of wheels to ensuring the efficiency of transmission systems, these bearings contribute to the overall performance and safety of vehicles. Their sealed design becomes especially crucial in preventing contaminants from affecting the bearings' functionality, making them indispensable components in automotive applications.

|

Manufacturing Precision Machinery

|

In the realm of manufacturing, precision is key, and 6206RS bearings align seamlessly with this requirement. These bearings find applications in various manufacturing machinery, such as conveyor systems, where their ability to handle both radial and axial loads comes into play. The dimensions of 30x62x16 make them suitable for different machinery configurations, providing manufacturers with a reliable solution for enhancing operational efficiency. |

|

Robotics and Automation |

With the rise of robotics and automation, the demand for bearings that can endure high-speed and high-load conditions has surged. 6206RS bearings, with their optimal dimensions and sealed construction, find their place in the heart of robotic systems. Whether in robotic arms, joints, or conveyor belts within automated processes, these bearings contribute to the precision and reliability required in modern industrial automation. |

|

Real-world Performance |

To truly grasp the impact of 6206RS bearings across industries, let's delve into a couple of case studies. In an automotive manufacturing plant, the implementation of these bearings led to a significant reduction in downtime due to their enhanced durability and longevity. Similarly, in a precision machining facility, the incorporation of 6206RS bearings resulted in improved machining accuracy, showcasing their influence on the overall performance of the machinery. |

As we navigate through the diverse applications and real-world examples, it becomes evident that 6206RS bearings transcend conventional bearings, offering a combination of precision, reliability, and durability that significantly contributes to the high-performance standards expected across various industries.

Performance Metrics and Durability

In our exploration of the high-performance realm of bearings, the 6206RS 30x62x16 Sealed Ball Bearings take center stage. Key aspects of performance metrics and durability are dissected for the engineering brilliance that drives these bearings to perform well in demanding applications.

Understanding Load Capacity

6206RS bearings boast an exceptional load-carrying capacity, making them indispensable in applications where heavy radial and axial loads are prevalent. The nominal dimensions of 30x62x16 indicate a bearing that can handle substantial forces, providing stability and reliability in various industrial setups. The inherent design, coupled with high-quality materials, contributes to a load capacity that exceeds conventional expectations.

Speed Rating Excellence

In the fast-paced world of machinery, the speed at which bearings can operate is a defining factor. 6206RS bearings exhibit an impressive speed rating, ensuring smooth and efficient rotation even under high-speed conditions. This attribute is particularly crucial in applications such as conveyor systems, where the precise movement of materials relies on the bearings' ability to maintain speed without compromising performance.

Empirical Insights: Durability Unveiled

To truly appreciate the durability of 6206RS bearings, let's turn our attention to empirical insights. In a rigorous testing environment, these bearings demonstrated an extended service life compared to traditional counterparts. The sealed design plays a pivotal role in preventing contamination, ensuring that the internal components remain well-lubricated and protected from external factors. This robust construction translates into bearings that withstand the test of time, reducing maintenance frequency and enhancing overall operational efficiency.

Real-world Applications

To contextualize these performance metrics, consider an industrial scenario where machinery operates under heavy loads and high speeds. The implementation of 6206RS bearings led to a notable increase in efficiency, minimizing downtime and contributing to substantial cost savings. These real-world applications underscore the practical implications of the impressive performance metrics and durability inherent in these sealed ball bearings.

|

Specification |

SKF 6206RS |

FAG 6206RS |

NTN 6206RS |

|

Dimensions (mm) |

30x62x16 |

30x62x16 |

30x62x16 |

|

Load Capacity (kN) |

High |

High |

High |

|

Speed Rating (rpm) |

Excellent |

Impressive |

High |

|

Sealing Design |

Contact Seal |

Contact Seal |

Contact Seal |

|

Material |

Premium Steel |

High-Quality Steel |

Robust Steel |

|

Durability |

Extended Service Life |

Durable Construction |

Long Operational Life |

|

Applications |

Versatile Applications |

Broad Range of Uses |

Diverse Industrial Uses |

|

Brand Reputation |

SKF - Renowned Quality |

FAG - Trusted Heritage |

NTN - Reliable Solutions |

Advantages Over Conventional Bearings

Navigating the cutting-edge landscape of high-performance bearings, the 6206RS 30x62x16 Sealed Ball Bearings emerge as a beacon of innovation in the field of precision engineering. This article delves into the intricacies of these bearings, shedding light on their specifications, applications, and the distinct advantages that position them as frontrunners in various industries.

Unveiling the Dimensions and Design

At the heart of the 6206RS bearings lies a meticulous design defined by the dimensions of 30x62x16 mm. The sealed ball configuration is not just a testament to their structural integrity but also a shield against external elements, making these bearings exceptionally versatile across an array of applications.

The Performance Benchmark

As we navigate through the realm of high-performance bearings, it becomes evident that the 6206RS sets a benchmark for superior performance. In , we'll explore how these bearings outshine their conventional counterparts, delivering unparalleled efficiency and longevity.

Precision and Longevity

Comparing 6206RS with conventional bearings unveils a stark contrast in performance and longevity. The precision with which these bearings operate translates to heightened load-carrying capacity and impeccable speed ratings. This precision, coupled with the robust construction, translates to a prolonged service life, minimizing downtime and maintenance costs.

Advantages Over Conventional Bearings

Now, let's delve into the specific advantages that make the 6206RS a standout choice in high-performance applications.

Superior Load-Carrying Capacity

Boldly surpassing conventional bearings, the 6206RS exhibits a superior load-carrying capacity. This prowess is particularly crucial in industrial settings where heavy loads are commonplace. The bearings' ability to shoulder substantial loads with ease ensures optimal performance even in demanding conditions.

Enhanced Speed Ratings

The speed at which bearings operate is a critical factor in various applications. Here, the 6206RS shines with enhanced speed ratings, making it a preferred choice for machinery and systems where rotational speed is a key consideration. This advantage contributes to the overall efficiency of operations.

Sealed Design for Unmatched Protection

One of the defining features of the 6206RS is its sealed ball design. This design not only enhances the overall performance by minimizing friction but also acts as a formidable barrier against contaminants. In environments prone to dust, moisture, or debris, the sealed design ensures consistent and reliable operation.

Conclusion

In conclusion, the unveiling of 6206RS bearings marks a significant stride in the realm of high-performance bearings. Their dimensions, precision, and sealed design collectively position them as leaders in the industry. With advantages ranging from superior load-carrying capacity and enhanced speed ratings to a sealed design for unmatched protection, these bearings navigate the challenges of high-performance applications with unparalleled efficiency and longevity. As industries evolve, the 6206RS remains at the forefront, symbolizing innovation, reliability, and a commitment to excellence.

Installation and Maintenance Practices

6206RS Sealed Ball Bearingsrepresent a pinnacle of precision engineering, offering unparalleled performance and reliability in various industrial applications.

Understanding 6206RS Sealed Ball Bearings

6206RS Sealed Ball Bearings are engineered to meet the demands of modern machinery and equipment. Their design features a sealed configuration, which not only enhances their durability but also protects against contamination, ensuring smooth and reliable operation even in harsh environments.

Proper Installation Procedures

The proper installation of 6206RS bearings is crucial for maximizing their performance and longevity. Here are some key insights into the installation process:

|

Ensure Cleanliness |

Before installation, thoroughly clean the mounting surfaces to remove any dirt, debris, or old lubricant that could affect the performance of the bearings. |

|

Use Proper Tools |

Use precision tools and equipment to install the bearings accurately and securely. Avoid applying excessive force, as this could damage the bearings or their mounting surfaces. |

|

Correct Alignment |

Ensure proper alignment of the bearings during installation to prevent misalignment, which can lead to premature wear and reduced performance. |

Maintenance Practices for Sustained High Performance

To ensure sustained high performance and longevity of 6206RS bearings, regular maintenance is essential. Here are some maintenance practices to follow:

- Lubrication: Regularly lubricate the bearings with the recommended lubricant to minimize friction and wear. Follow the manufacturer's guidelines for the appropriate lubrication intervals and types of lubricants to use.

- Inspections: Periodically inspect the bearings for signs of wear, damage, or contamination. Replace any damaged or worn bearings promptly to prevent further issues.

providing effective protection against contamination. Replace any damaged or worn seals as needed.

Conclusion

In conclusion, proper installation and maintenance practices are essential for maximizing the performance and longevity of 6206RS Sealed Ball Bearings. By following these guidelines, you can ensure smooth operation and reliable performance of these precision-engineered bearings in a wide range of industrial applications.

Conclusion

In conclusion, the journey through the realm of 6206RS Sealed Ball Bearings unveils a landscape of unparalleled performance and reliability. Let's summarize the key takeaways:

Precision in Design:

- The precision engineering of 6206RS bearings, reflected in their dimensions of 30x62x16, sets them apart. This design ensures optimal functionality across various applications, contributing to their high-performance reputation.

Sealed for Success:

- The sealed design of these bearings not only protects against external contaminants but also enhances their durability. This feature is instrumental in applications where maintaining a clean and efficient operational environment is crucial.

Performance Metrics:

- Analyzing the performance metrics, including load capacity and durability, reveals the robust nature of 6206RS bearings. These metrics highlight their suitability for demanding industrial environments.

Versatility Across Industries:

- The diverse applications of 6206RS bearings showcase their versatility. From automotive machinery to industrial equipment, these bearings consistently deliver exceptional performance, meeting the standards of various industries.

Elevating Technological Standards:

- The impact of 6206RS bearings extends beyond individual applications. By consistently delivering high performance and reliability, these bearings contribute to elevating technological standards in the realm of advanced bearing technology.

As we navigate the complexities of high-performance bearings, the significance of 6206RS becomes evident. Whether it's ensuring precision in design, maintaining durability through a sealed configuration, or meeting rigorous performance metrics, these bearings embody excellence in the world of advanced bearing technology.

In essence, the journey of exploring and understanding 6206RS Sealed Ball Bearings is a testament to their enduring impact on technological standards. They stand as a symbol of reliability, precision, and excellence in the ever-evolving landscape of advanced bearing solutions.

FAQs: Common Questions About 6206RS 30x62x16 Sealed Ball Bearings

What are the Dimensions of 6206RS Bearings?

6206RS bearings boast dimensions of 30x62x16, representing their inner diameter, outer diameter, and width, respectively. These specifications play a crucial role in determining their compatibility with various applications.

How Does the Sealed Design Enhance Performance?

The sealed configuration of 6206RS bearings provides a protective shield against contaminants such as dust and moisture. This design not only prolongs the bearing's lifespan but also ensures consistent performance in demanding environments.

What Industries Benefit from 6206RS Bearings?

These bearings find applications across diverse industries, including automotive, manufacturing, and machinery. Their versatility makes them suitable for environments where precision, reliability, and high performance are paramount.

Can 6206RS Bearings Handle Heavy Loads?

Absolutely. One of the distinguishing features of 6206RS bearings is their robust load-carrying capacity. Whether it's handling radial or axial loads, these bearings demonstrate exceptional strength and resilience.

How Do I Ensure Authenticity When Sourcing 6206RS Bearings?

Authenticity is crucial when procuring high-performance bearings. Look for reputable suppliers and ensure proper certification. Counterfeit bearings can compromise performance and jeopardize the efficiency of your machinery.

Are These Bearings Suitable for High-Speed Applications?

Yes, the precision engineering of 6206RS bearings, combined with their sealed design, makes them well-suited for high-speed applications. They maintain stability and reduce friction, even in demanding operational conditions.

What Maintenance Practices Are Recommended?

Proper maintenance is key to maximizing the longevity and performance of 6206RS bearings. Regular lubrication, inspections for wear and tear, and adherence to manufacturer guidelines ensure these bearings consistently deliver high performance.

As we navigate the frequently asked questions about 6206RS 30x62x16 Sealed Ball Bearings, it becomes evident that these bearings are not just components; they are enablers of high-performance machinery. Whether it's their dimensions, sealed design, versatile applications, load-handling capabilities, authenticity, suitability for high-speed operations, or recommended maintenance practices, 6206RS bearings stand out as reliable, efficient, and indispensable in the world of advanced bearing technology.