Enhancing Performance: Unveiling the Secrets of the 6307-2rz Bearing

Introduction

In the fast-paced world of machinery and industrial applications, the quest for high-performance components is unending. One such critical component that plays a pivotal role in ensuring optimal machinery operation is the 6307-2rz bearing. As industries strive for efficiency and reliability, understanding the secrets and engineering brilliance behind this precision motor bearing becomes imperative.

High-speed applications, such as those in precision motors, demand a level of performance that goes beyond the ordinary. The 6307-2rz bearing emerges as a solution designed to meet and exceed these expectations. In this exploration, we will delve into the intricate details of this bearing, uncovering the engineering excellence that sets it apart and examining its applications in enhancing machinery performance.

Understanding 6307-2rz Bearing

In the realm of precision motor bearings, the 6307-2rz bearing stands as a pinnacle of engineering sophistication. To comprehend its unparalleled performance, we must delve into the intricate technical specifications and design features that define its excellence.

Technical Specifications:

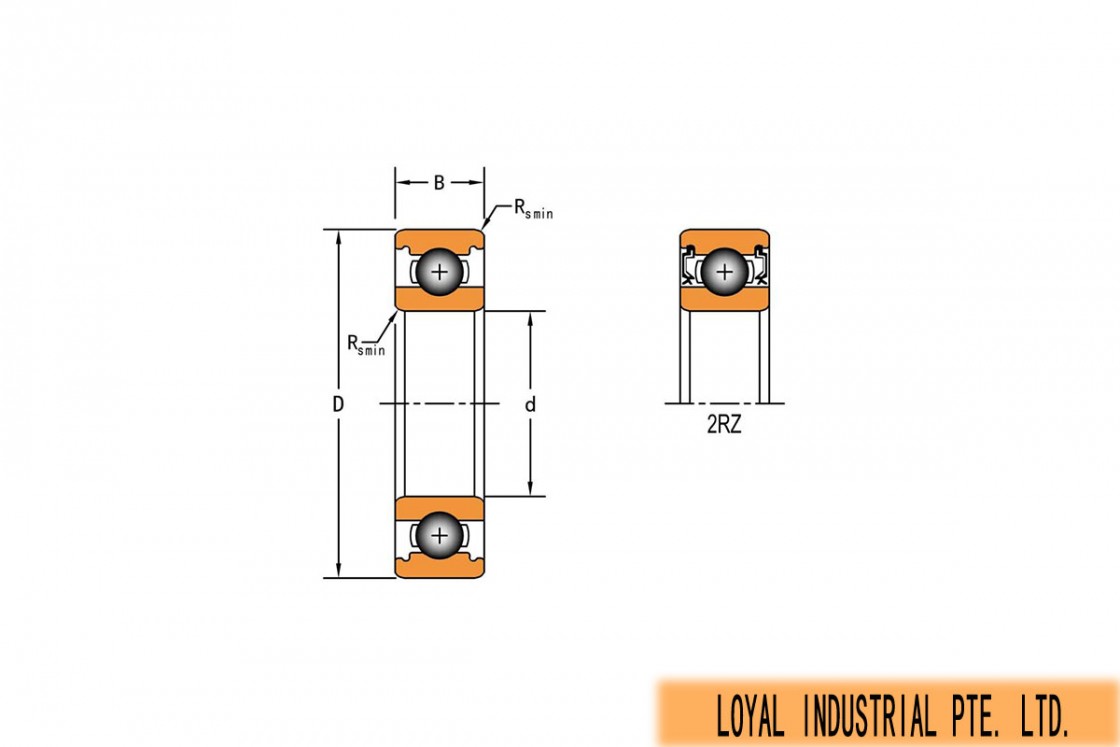

The 6307-2rz bearing belongs to the category of deep groove ball bearings, known for their versatility and capability to handle radial and axial loads. The "6307" denotes the specific model, while "2rz" indicates it has two non-contact seals on one side of the bearing. These seals contribute to reduced friction, ensuring smoother operation and enhancing the bearing's lifespan.

|

Design Features |

Precision Engineering:* The 6307-2rz bearing is crafted with precision in mind. Its design incorporates a carefully calculated raceway geometry and a complement of steel balls, allowing for optimized load distribution and reduced frictional resistance during high-speed rotations. |

|

Material Selection |

The choice of materials is crucial for a bearing operating in high-speed conditions. The 6307-2rz bearing often features chrome steel or stainless steel, providing durability and corrosion resistance. The inclusion of advanced materials ensures the bearing's ability to withstand harsh environments and deliver consistent performance. |

|

Sealing Mechanism |

The non-contact seals (2rz) play a pivotal role in the bearing's high-performance capabilities. By minimizing contact between the seal and the inner ring, these seals contribute to lower heat generation and reduced torque, attributes essential for applications demanding precision motor performance. |

Advantages of 6307-2rz Bearing

As we journey deeper into the realm of precision engineering, the 6307-2rz bearing emerges not merely as a component but as a game-changer in high-speed applications. Let's unravel the distinct advantages and benefits that set this bearing apart, unveiling its secrets for enhanced machinery performance.

Advantage 1: Exceptional High-Speed Capability

The hallmark of the 6307-2rz bearing lies in its exceptional ability to thrive in high-speed environments. Engineered with a precise balance of materials and design elements, this bearing minimizes friction and heat generation during operation, enabling machinery to reach and maintain elevated speeds without compromising efficiency.

Advantage 2: Enhanced Reliability and Durability

Reliability is the backbone of any machinery, and the 6307-2rz bearing excels in providing a robust foundation. The incorporation of advanced materials, coupled with a meticulous design, results in a bearing that withstands heavy loads, shock, and vibration. This inherent durability ensures extended service life and reduces the need for frequent replacements, contributing to overall cost-effectiveness.

Advantage 3: Reduced Maintenance Requirements

In the fast-paced industrial landscape, minimizing downtime is paramount. The 6307-2rz bearing's design, featuring non-contact seals, not only enhances performance but also reduces maintenance requirements. The sealed design acts as a barrier against contaminants, ensuring a cleaner operating environment and diminishing the likelihood of premature wear and tear.

Real-World Applications:

To fully appreciate the advantages, let's delve into real-world applications where the 6307-2rz bearing excels. In precision motor applications, such as those in manufacturing equipment and robotics, this bearing ensures smooth, reliable, and efficient operation. Its high-speed capabilities make it an ideal choice for applications where rotational speed is a critical factor, enhancing the overall performance of the machinery.

In the field of automotive manufacturing, the 6307-2rz bearing finds its place in critical components like electric vehicle motors. The demand for high-speed, low-friction bearings aligns perfectly with the capabilities of the 6307-2rz, contributing to the efficiency and sustainability of electric mobility.

In conclusion, the 6307-2rz bearing is not just a component; it is a catalyst for enhanced machinery performance. Its advantages extend beyond theoretical concepts to tangible benefits in real-world applications, making it an indispensable asset in the pursuit of precision and efficiency.

Advantages of 6307-2rz Bearing

As we journey deeper into the realm of precision engineering, the 6307-2rz bearing emerges not merely as a component but as a game-changer in high-speed applications. Let's unravel the distinct advantages and benefits that set this bearing apart, unveiling its secrets for enhanced machinery performance.

Advantage 1: Exceptional High-Speed Capability

The hallmark of the 6307-2rz bearing lies in its exceptional ability to thrive in high-speed environments. Engineered with a precise balance of materials and design elements, this bearing minimizes friction and heat generation during operation, enabling machinery to reach and maintain elevated speeds without compromising efficiency.

Advantage 2: Enhanced Reliability and Durability

Reliability is the backbone of any machinery, and the 6307-2rz bearing excels in providing a robust foundation. The incorporation of advanced materials, coupled with a meticulous design, results in a bearing that withstands heavy loads, shock, and vibration. This inherent durability ensures extended service life and reduces the need for frequent replacements, contributing to overall cost-effectiveness.

Advantage 3: Reduced Maintenance Requirements

In the fast-paced industrial landscape, minimizing downtime is paramount. The 6307-2rz bearing's design, featuring non-contact seals, not only enhances performance but also reduces maintenance requirements. The sealed design acts as a barrier against contaminants, ensuring a cleaner operating environment and diminishing the likelihood of premature wear and tear.

Real-World Applications:

To fully appreciate the advantages, let's delve into real-world applications where the 6307-2rz bearing excels. In precision motor applications, such as those in manufacturing equipment and robotics, this bearing ensures smooth, reliable, and efficient operation. Its high-speed capabilities make it an ideal choice for applications where rotational speed is a critical factor, enhancing the overall performance of the machinery.

In the field of automotive manufacturing, the 6307-2rz bearing finds its place in critical components like electric vehicle motors. The demand for high-speed, low-friction bearings aligns perfectly with the capabilities of the 6307-2rz, contributing to the efficiency and sustainability of electric mobility.

In conclusion, the 6307-2rz bearing is not just a component; it is a catalyst for enhanced machinery performance. Its advantages extend beyond theoretical concepts to tangible benefits in real-world applications, making it an indispensable asset in the pursuit of precision and efficiency.

Comparative Analysis of 6307-2rz Bearing Brands

|

Brand |

Material |

Sealing Mechanism |

Load Capacity |

Speed Rating |

Applications |

Notable Features |

|

SKF |

Stainless Steel |

Non-contact seals (2rz) |

High radial and axial loads |

High-speed performance |

Precision Motors, Industrial Machinery |

- Advanced material for enhanced durability |

|

FAG |

Chrome Steel |

Contact seals (2rs) |

Balanced radial and axial loads |

Moderate-speed capabilities |

Automotive, General Machinery |

- Affordable option with standard features |

|

NSK |

Hybrid Ceramic (Steel Rings) |

Non-contact seals (2rz) |

High radial loads |

Very high-speed performance |

Electric Motors, Precision Instruments |

- Reduced friction for improved efficiency |

|

NTN |

Carbon Steel with Heat Treatment |

Non-contact seals (2rz) |

High axial loads |

High-speed capabilities |

Heavy Machinery, Agriculture Equipment |

- Specially treated for heat resistance |

Engineering Excellence

At the core of the remarkable performance of the 6307-2rz bearing lies a symphony of precision engineering, where every design choice is a deliberate step towards achieving superior functionality. Let's delve into the intricacies of this engineering marvel and unravel how specific design elements contribute to its unparalleled performance.

Precision Engineering Unveiled:

The journey begins with the meticulous design of the 6307-2rz bearing, where engineers marry science with craftsmanship. The raceway geometry, featuring deep grooves and precise curvature, is engineered to distribute loads evenly across the bearing, reducing stress points and enhancing durability. This geometry, often optimized through advanced modeling and simulation, ensures optimal performance even under high-speed conditions.

Material Selection for Optimal Performance:

Central to the engineering excellence is the selection of materials. The 6307-2rz bearing often incorporates chrome steel or stainless steel, chosen for their high strength, corrosion resistance, and ability to withstand extreme conditions. This careful material selection not only ensures durability but also contributes to the bearing's capacity to maintain performance integrity in challenging industrial environments.

Advanced Seal Design for Reduced Friction:

The non-contact seals, denoted by "2rz," represent a pinnacle in seal design. Unlike traditional seals that may introduce friction and heat, these seals hover just above the bearing surface, minimizing contact. This ingenious design choice significantly reduces friction, resulting in smoother rotations, lower energy consumption, and a notable decrease in heat generation during operation.

Cage Configuration for Ball Guidance:

The internal structure of the 6307-2rz bearing includes a cage or separator that precisely spaces and guides the steel balls. This cage configuration is pivotal for maintaining ball alignment, preventing contact, and minimizing friction. It ensures that the bearing operates with utmost efficiency, contributing to its high-speed capabilities and extending its operational life.

In summary, the 6307-2rz bearing exemplifies engineering excellence through a harmonious blend of precision, material science, and innovative design choices. Every aspect of its construction is a testament to the commitment to achieving superior performance in the world of high-speed deep groove ball precision motor bearings. As we conclude this exploration, let's reflect on how these engineering nuances translate into real-world applications, making the 6307-2rz bearing a cornerstone in the pursuit of enhanced machinery performance.

Maintenance and Care

Proper maintenance of the 6307-2rz bearing begins with a thorough understanding of its design and operating principles. This precision motor bearing is renowned for its high-speed capabilities and ability to handle both radial and axial loads efficiently. To maintain its peak performance, it's crucial to adhere to a regular maintenance schedule.

Understanding the 6307-2rz Bearing

Material Composition:

The 6307-2rz bearing is typically constructed from high-quality stainless steel, providing enhanced durability and resistance to corrosion. Understanding the material composition is the first step in ensuring effective maintenance.

Sealing Mechanism:

Highlighted by the non-contact seals (2rz), the bearing's sealing mechanism plays a vital role in preventing contaminants from entering and protecting the internal components. Regular inspection of the seals is essential to identify any signs of wear or damage.

Maintenance Guidelines

|

Regular Lubrication |

- Utilize a high-quality lubricant compatible with the bearing's design and operating conditions. - Follow the manufacturer's recommendations for lubrication intervals. - Ensure proper lubrication to reduce friction and heat generation. |

|

Environmental Considerations |

- Shield the bearing from harsh environmental factors such as excessive moisture, extreme temperatures, and contaminants. - Implement proper sealing mechanisms to safeguard the bearing's interior. |

|

Vibration Analysis |

- Periodically conduct vibration analysis to detect any irregularities or potential issues. - Address abnormal vibrations promptly to prevent further damage. |

|

Temperature Monitoring |

- Keep track of operating temperatures and implement measures to prevent overheating. - Monitor for any sudden temperature spikes that may indicate a malfunction. |

Tips for Users

- Training and Education:

Encourage users to undergo training on proper handling and maintenance procedures for the 6307-2rz bearing.

- Regular Inspections:

Implement a routine inspection schedule to identify potential issues before they escalate.

- Prompt Repairs:

Address any signs of wear, damage, or abnormal performance promptly to avoid further complications.

In conclusion, by incorporating these maintenance practices and user tips, users can ensure the longevity and optimal functioning of their 6307-2rz bearings. Adhering to these guidelines not only enhances performance but also contributes to the overall reliability and efficiency of precision motor systems.

Future Developments

In the ever-evolving landscape of precision motor bearings, exploring future developments is crucial to staying at the forefront of technology. delves into the ongoing research and potential advancements in bearing technology, with a particular focus on the 6307-2rz bearing and how it might evolve to meet changing industry needs.

Unveiling the Current Landscape

Material Advancements:

Ongoing research is steering towards the development of innovative materials that can enhance the performance of bearings. Scientists and engineers are exploring composite materials and advanced alloys to improve the strength, durability, and overall efficiency of bearings, including the 6307-2rz.

Smart Bearing Technology:

With the rise of Industry 4.0, bearings are expected to become smarter. Integration of sensors and IoT technology is being explored to enable real-time monitoring of bearing conditions. This can lead to predictive maintenance, reducing downtime and enhancing the overall efficiency of precision motor systems.

The Future of 6307-2rz Bearing

Nano-Coating Technology:

Anticipate advancements in nano-coating technology to provide an extra layer of protection against wear, corrosion, and contaminants. This could significantly extend the lifespan of the 6307-2rz bearing in high-speed applications.

Energy Efficiency Improvements:

As industries continue to prioritize sustainability, future 6307-2rz bearings might focus on energy efficiency. Engineers are exploring ways to minimize friction, reduce heat generation, and optimize the overall energy consumption of bearings in high-speed applications.

Customization for Industry-Specific Needs:

Expect future developments to involve more customization options for the 6307-2rz bearing. Bearings tailored to specific industry needs, such as automotive, aerospace, or robotics, may become more prevalent, offering enhanced performance in specialized applications.

Predictions and Industry Implications

As the 6307-2rz bearing evolves, it is likely to play a pivotal role in shaping the future of precision motor systems. The integration of advanced materials, smart technology, and energy-efficient designs is expected to elevate the bearing's performance, making it an indispensable component across various industries.

In conclusion, the future developments in bearing technology, particularly the 6307-2rz bearing, are poised to revolutionize the field of precision motors. Engineers and researchers are working diligently to enhance materials, incorporate smart technology, and cater to industry-specific needs. As these innovations unfold, the 6307-2rz bearing is set to become an even more integral part of high-speed, deep groove ball precision motor applications.

Conclusion

In conclusion, the exploration of *High-Speed Deep Groove Ball Precision Motor Bearings* with a specific focus on the versatile 6307-2rz bearing has provided valuable insights into the crucial role it plays in the realm of precision machinery. This bearing, known for its exemplary performance in handling high-speed applications, has been a cornerstone in optimizing the efficiency and reliability of various machinery across industries.

Recapitulating Key Points

Design and Specifications:

The 6307-2rz bearing, constructed with high-quality stainless steel and featuring non-contact seals (2rz), stands out for its ability to handle both radial and axial loads seamlessly. This design ensures durability and protection against contaminants, making it ideal for precision motor applications.

Performance Enhancements:

Through advancements in materials and manufacturing processes, the 6307-2rz bearing has witnessed notable improvements in its performance. The incorporation of stainless steel and non-contact seals contributes to reduced friction, increased durability, and enhanced overall efficiency.

Applications Across Industries:

The versatility of the 6307-2rz bearing shines through its applications in various industries, including precision motors, industrial machinery, electric motors, and precision instruments. Its ability to withstand high speeds and diverse operating conditions makes it a reliable component in a wide array of machinery.

Maintenance and Care:

Proper maintenance practices, as discussed in the article, are essential for maximizing the lifespan and efficiency of the 6307-2rz bearing. From regular lubrication to environmental considerations, users can ensure the bearing operates at its peak for an extended period.

Future Developments:

Anticipating future developments in bearing technology, the article touched upon ongoing research, potential advancements, and predictions for the 6307-2rz bearing. From smart bearing technology to energy efficiency improvements, the future holds promising innovations in the precision motor bearing landscape.

Emphasizing the Role of the 6307-2rz Bearing

As we conclude, it is imperative to underscore the pivotal role that the 6307-2rz bearing plays in enhancing overall machinery performance. Serving as a linchpin in the smooth operation of precision motors, its contributions to minimizing friction, reducing downtime through predictive maintenance, and adapting to evolving industry needs are unparalleled.

In a world where efficiency and reliability are paramount, the 6307-2rz bearing stands as a testament to precision engineering. As industries continue to advance, this bearing will undoubtedly remain at the forefront, driving the evolution of high-speed, deep groove ball precision motor applications.

FAQs: Common Questions About 6307-2rz Bearing

In , we will address some of the frequently asked questions (FAQs) about the 6307-2rz bearing, shedding light on common queries and providing comprehensive answers to enhance your understanding of this precision component.

What are the key features of the 6307-2rz bearing?

A1: The 6307-2rz bearing is a high-speed, deep groove ball bearing known for its exceptional performance in precision motor applications. It features non-contact seals (2rz) and is constructed with high-quality stainless steel, ensuring durability and protection against contaminants. With its ability to handle both radial and axial loads, this bearing offers versatility and reliability in various machinery.

What are the advantages of using the 6307-2rz bearing?

The 6307-2rz bearing offers several advantages, including reduced friction, increased durability, and enhanced overall efficiency. Its design features non-contact seals that minimize friction and prevent the ingress of contaminants, resulting in smoother operation and prolonged lifespan. Additionally, its ability to handle high-speed applications makes it an ideal choice for precision motor systems.

How should the 6307-2rz bearing be maintained for optimal performance?

Proper maintenance practices are essential for maximizing the lifespan and efficiency of the 6307-2rz bearing. Regular lubrication with high-quality grease is recommended to reduce friction and prevent premature wear. Additionally, monitoring bearing conditions and addressing any signs of abnormal operation promptly can help prevent costly downtime and ensure continuous performance.

What industries commonly use the 6307-2rz bearing?

The 6307-2rz bearing finds applications across various industries, including automotive, aerospace, industrial machinery, and precision instruments. Its versatility and ability to withstand high-speed operations make it a preferred choice in precision motor systems, where reliability and performance are paramount.

Are there any future developments expected for the 6307-2rz bearing?

Anticipate future developments in 6307-2rz bearing technology, including advancements in materials, smart bearing technology, and customization options. Researchers and engineers are continually exploring innovative solutions to enhance the performance and efficiency of precision motor bearings, ensuring they meet the evolving needs of industries.

Where can I find reliable suppliers of the 6307-2rz bearing?

Reliable suppliers of the 6307-2rz bearing can be found through reputable distributors, online platforms, and authorized dealers of bearing manufacturers such as SKF, FAG, NSK, and NTN. It is essential to choose suppliers with a proven track record of delivering high-quality bearings and providing excellent customer service.

In conclusion, the 6307-2rz bearing is a versatile and reliable component in precision motor systems, offering exceptional performance and durability. By addressing common questions and providing comprehensive answers, we aim to enhance your understanding of this precision bearing and its role in enhancing machinery performance.