Enhancing Performance: Full Complement Cylindrical Roller Radial Bearings in High-Speed Applications

1 Introduction

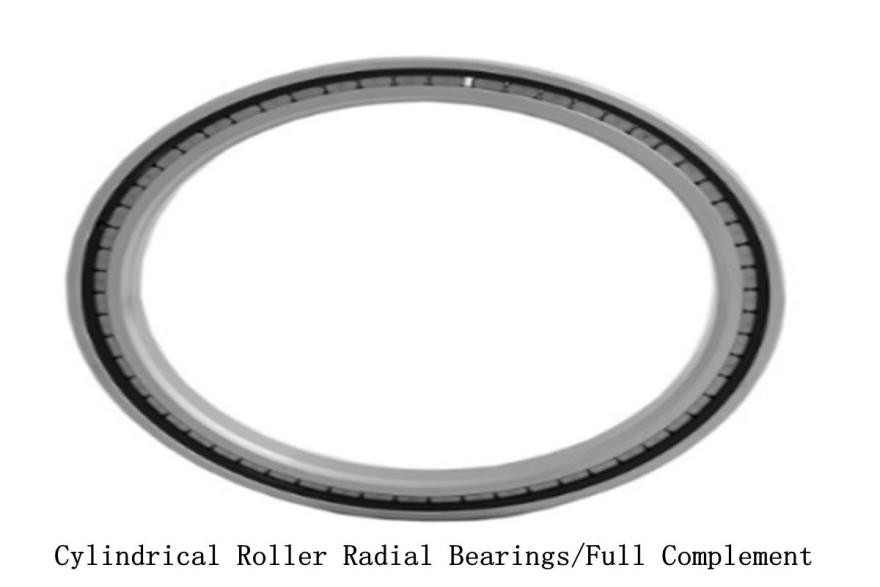

In the realm of industrial machinery, the efficiency and reliability of components play a pivotal role in determining overall performance. Cylindrical roller radial bearings stand as indispensable components within various machinery, facilitating smooth rotation and load-bearing capabilities. These bearings are fundamental elements in a wide array of applications, ranging from automotive to heavy machinery industries.

Full complement cylindrical roller radial bearings, a specialized variant of cylindrical roller bearings, possess distinctive characteristics that set them apart. Unlike traditional bearings, which contain a cage to separate rollers, full complement bearings feature a maximum complement of rollers, enabling them to accommodate heavier loads and operate at higher speeds with enhanced stability.

High-speed applications present unique challenges and demands on machinery components. From conveyor systems to rotating equipment, the need for precision, durability, and performance is paramount. Full complement cylindrical roller radial bearings excel in such environments, offering heightened load-carrying capacity and reduced frictional resistance, thereby enhancing overall performance.

As industries continue to push the boundaries of speed and efficiency, the role of full complement cylindrical roller radial bearings becomes increasingly significant. Understanding their design principles, advantages, and applications is crucial for engineers, designers, and maintenance professionals striving to optimize machinery performance in high-speed environments.

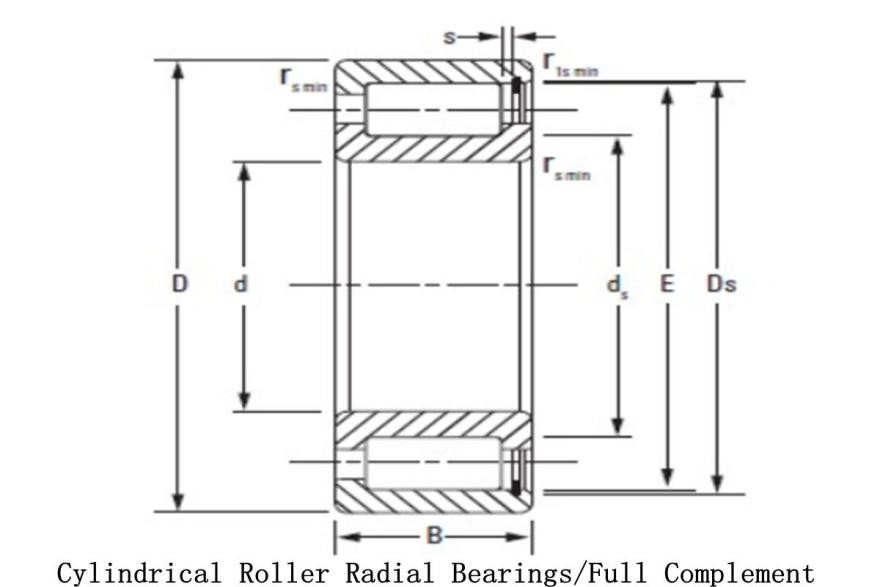

2 Design and Structure of Full Complement Cylindrical Roller Radial Bearings

Detailed Description of Full Complement Bearing Design:

Full complement cylindrical roller radial bearings are meticulously engineered to fulfill demanding requirements in high-speed applications. Unlike conventional bearings that incorporate cages to space out rollers, full complement bearings feature a design that maximizes roller quantity within the bearing assembly. This design choice ensures that there is no gap between adjacent rollers, allowing for a higher load-carrying capacity and improved performance under heavy loads.

Comparison with Standard Bearings: Advantages and Differences:

When compared to standard bearings, full complement cylindrical roller radial bearings offer several distinct advantages. The absence of a cage in full complement bearings results in a higher number of rollers being accommodated within the bearing assembly. This leads to enhanced load distribution across the rollers, reducing stress concentrations and increasing load-carrying capability. Additionally, the elimination of the cage reduces frictional resistance, thereby improving efficiency and extending bearing life. These features make full complement bearings particularly well-suited for high-speed applications where reliability and performance are critical.

Analysis of Bearing Materials and Manufacturing Processes for High-Speed Performance:

The performance of full complement cylindrical roller radial bearings in high-speed applications is not solely dependent on their design but also on the materials used and the manufacturing processes employed. High-quality materials such as chrome steel or stainless steel are often utilized to ensure durability and resistance to wear, particularly under high-speed and high-load conditions. Additionally, advanced manufacturing techniques, including precision grinding and heat treatment, are employed to achieve tight tolerances and optimal surface finish, further enhancing the performance of the bearings.

In conclusion, the design and structure of full complement cylindrical roller radial bearings are tailored to meet the rigorous demands of high-speed applications. By maximizing load-carrying capacity, minimizing friction, and utilizing high-quality materials and manufacturing processes, these bearings play a crucial role in enhancing the performance and reliability of machinery operating at elevated speeds.

3 Brand Introductions: Cylindrical Roller Radial Bearings/Full Complement

In the industrial sector, Cylindrical Roller Radial Bearings/Full Complement are key products for many leading brands. These brands have earned trust and recognition from global customers through their innovative designs, high-quality manufacturing, and outstanding performance. Here are brief introductions to several major brands:

1. SKF:

SKF is one of the world's leading bearing manufacturers, renowned for its Cylindrical Roller Radial Bearings/Full Complement products' excellent quality and reliability. SKF's bearing products cover various sizes, load capacities, and applicable environments, meeting the diverse needs of various industrial applications. SKF's global service network and professional team ensure timely technical support and after-sales service, enabling customers to achieve optimal performance and value.

2. NTN:

NTN is a well-established bearing manufacturer with a long history, highly acclaimed for its Cylindrical Roller Radial Bearings/Full Complement products' high precision and durability. NTN's bearing products are widely used in automotive, aerospace, mechanical manufacturing, and other fields. With stable performance and high-quality service, NTN has won the trust of global customers.

3. NSK:

NSK is one of the world's leading manufacturers of bearings and motion control products, with its Cylindrical Roller Radial Bearings/Full Complement series enjoying a high reputation in the industry. NSK's bearing products are precision-engineered and stable in performance, meeting various high-speed and high-load application requirements. Committed to technological innovation and quality management, NSK provides reliable bearing solutions and quality service support to customers.

4. Timken:

Timken is a renowned manufacturer of engineered bearings and power transmission products, known for its Cylindrical Roller Radial Bearings/Full Complement products' excellent performance and durability. Timken's bearing products are widely used in heavy machinery, aerospace, railways, and other fields. With reliability and performance advantages, Timken has gained wide market recognition.

5. Schaeffler:

As a global leader in bearing and power transmission system solutions, Schaeffler's Cylindrical Roller Radial Bearings/Full Complement products play a vital role in the industrial and automotive sectors. Schaeffler provides customers with high-performance bearing products and solutions through its outstanding engineering design and continuous innovation, helping them achieve business success and sustainable development.

|

Brand |

Description |

Key Features |

Applications |

|

SKF |

SKF is a global leader in bearing manufacturing, known for its high-quality and reliable products. |

- Excellent quality and reliability |

- Industrial machinery |

|

NTN |

NTN is a renowned bearing manufacturer with a long history, highly acclaimed for its precision and durability. |

- High precision and durability |

- Automotive systems |

|

NSK |

NSK is a leading manufacturer of bearings and motion control products, recognized for its precision engineering and stable performance. |

- Precision-engineered products |

- Industrial machinery |

|

Timken |

Timken is a well-known manufacturer of engineered bearings and power transmission products, appreciated for its excellent performance and durability. |

- Excellent performance and durability |

- Heavy machinery |

|

Schaeffler |

Schaeffler is a global leader in bearing and power transmission solutions, providing high-performance products and solutions through engineering excellence and innovation. |

- High-performance bearing solutions |

- Industrial machinery- Automotive systems |

These brands have garnered global customer favor with their rich experience, excellent technology, and professional services, playing an important role in the Cylindrical Roller Radial Bearings/Full Complement field. With continuous industrial technological advancement and growing market demand, these brands will continue to strive to provide more advanced and reliable products and solutions, creating greater value and success for customers.

4 Performance Enhancement in High-Speed Applications

Impact of Full Complement Bearings on High-Speed Machinery:

In the realm of high-speed applications, the performance of machinery is crucially dependent on the efficiency and reliability of its components. Among these components, full complement cylindrical roller radial bearings play a pivotal role in ensuring optimal performance. By virtue of their unique design, full complement bearings offer several key advantages that directly contribute to enhancing the performance of machinery operating at elevated speeds.

Advantages such as Increased Load Capacity and Reduced Friction:

One of the primary advantages of full complement cylindrical roller radial bearings in high-speed applications is their ability to accommodate heavier loads compared to standard bearings. The absence of a cage allows for a greater number of rollers to be packed into the bearing assembly, resulting in improved load distribution and enhanced load-carrying capacity. This increased load capacity is particularly beneficial in high-speed machinery, where the forces exerted on bearings are often substantial.

Additionally, the elimination of the cage in full complement bearings leads to a reduction in frictional resistance. With fewer mechanical constraints impeding the movement of rollers, friction between components is minimized, resulting in smoother operation and reduced energy consumption. This reduction in friction not only improves the efficiency of the machinery but also helps extend the service life of the bearings, thereby enhancing overall reliability.

Case Studies and Examples Demonstrating Performance Improvements:

Numerous case studies and real-world examples attest to the significant performance improvements achieved through the adoption of full complement cylindrical roller radial bearings in high-speed applications. In industries ranging from automotive manufacturing to aerospace engineering, the implementation of these bearings has resulted in tangible benefits such as increased productivity, reduced downtime, and enhanced operational efficiency.

For instance, in the automotive sector, where precision and reliability are paramount, manufacturers have turned to full complement bearings to support the high-speed rotation of engine components, transmission systems, and wheel assemblies. By replacing conventional bearings with full complement variants, automotive engineers have been able to achieve higher torque transmission, smoother operation, and improved fuel efficiency.

Similarly, in the field of industrial machinery, the use of full complement bearings has revolutionized the performance of high-speed equipment such as centrifugal pumps, turbines, and gearboxes. By harnessing the superior load-carrying capacity and reduced friction offered by these bearings, manufacturers have been able to push the limits of speed and efficiency, resulting in enhanced productivity and profitability.

In conclusion, the adoption of full complement cylindrical roller radial bearings represents a paradigm shift in the design and performance of machinery operating in high-speed applications. With their ability to increase load capacity, reduce friction, and improve overall efficiency, these bearings play a pivotal role in enhancing the performance and reliability of high-speed machinery across various industries.

5 Factors Influencing Performance

Consideration of Factors like Lubrication, Temperature, and Alignment:

In the realm of high-speed applications, the performance of machinery hinges not only on the quality of components like cylindrical roller radial bearings but also on various external factors that can influence their operation. Among these factors, lubrication, temperature, and alignment play pivotal roles in determining the overall performance and longevity of bearings.

|

Lubrication |

Adequate lubrication is essential for reducing friction and minimizing wear between bearing components. In high-speed applications, where rotational speeds are elevated, the selection of the appropriate lubricant and the frequency of lubrication intervals are critical considerations. Insufficient lubrication can lead to increased friction, elevated operating temperatures, and premature bearing failure. |

|

Temperature |

High-speed machinery often generates significant amounts of heat due to friction and mechanical stresses. Excessive temperatures can degrade the performance of bearings and compromise their structural integrity. Therefore, effective heat dissipation mechanisms, such as cooling systems or proper ventilation, must be implemented to maintain optimal operating temperatures and prevent thermal-induced damage. |

|

Alignment |

Proper alignment of bearing components is essential for ensuring smooth operation and uniform load distribution. Misalignment can result in uneven stress distribution, increased friction, and accelerated wear, ultimately leading to reduced performance and premature failure of bearings. Regular inspection and adjustment of alignment parameters are necessary to mitigate these issues and maintain optimal performance. |

Importance of Proper Installation and Maintenance for Optimal Performance:

The performance of full complement cylindrical roller radial bearings in high-speed applications is contingent upon their proper installation and ongoing maintenance. Improper installation procedures can introduce misalignments, uneven loading, or other mechanical issues that impair bearing performance. Therefore, adherence to manufacturer-recommended installation practices, including proper mounting techniques and torque specifications, is imperative to maximize bearing performance and longevity.

|

Aspect |

Importance |

|

Correct Installation |

-Ensures proper alignment and fitment of bearings, preventing premature wear and failure |

|

Adequate Lubrication |

- Provides necessary lubrication to reduce friction and wear between bearing components |

|

Regular Inspection |

- Allows for early detection of wear, damage, or abnormalities in bearing components |

|

Proper Handling |

- Prevents contamination, damage, or mishandling of bearings during storage, transportation, and installation |

|

Timely Replacement |

- Addresses worn or damaged bearings promptly to prevent further damage to machinery |

|

Training and Expertise |

- Ensures that personnel responsible for installation and maintenance are properly trained and knowledgeable |

Discussion on How Design Choices Affect Performance in High-Speed Environments:

In high-speed environments, the design choices made during the engineering and manufacturing of full complement cylindrical roller radial bearings can significantly impact their performance. Factors such as material selection, bearing geometry, and surface finish can influence load capacity, frictional characteristics, and overall durability.

For instance, the use of high-quality materials with superior mechanical properties, such as hardened steel or ceramic, can enhance bearing strength and resistance to fatigue under high-speed, high-load conditions. Likewise, optimizing bearing geometry to minimize contact stresses and improve load distribution can improve performance and extend service life.

In conclusion, factors such as lubrication, temperature, alignment, proper installation, and maintenance practices, along with thoughtful design considerations, collectively influence the performance of full complement cylindrical roller radial bearings in high-speed applications. By addressing these factors comprehensively, engineers and maintenance professionals can ensure optimal performance, reliability, and longevity of machinery operating at elevated speeds.

6 Conclusion and Future Outlook

In conclusion, the utilization of full complement cylindrical roller radial bearings represents a significant advancement in enhancing the performance of machinery operating in high-speed applications. Throughout this discourse, we have explored the various facets of these specialized bearings, from their unique design and structure to their profound impact on performance enhancement.

Summary of the Benefits of Full Complement Bearings in High-Speed Applications:

Full complement bearings offer a multitude of benefits that are particularly advantageous in high-speed environments. By maximizing load-carrying capacity, minimizing friction, and improving efficiency, these bearings contribute to smoother operation, increased productivity, and reduced downtime in industrial machinery. Their ability to withstand heavy loads and operate at elevated speeds makes them indispensable components in a wide range of applications, including automotive, aerospace, and manufacturing.

Reflection on Potential Future Developments and Innovations:

Looking ahead, the future of full complement cylindrical roller radial bearings holds promising prospects for further advancements and innovations. As industries continue to push the boundaries of speed, efficiency, and performance, there is a growing demand for bearings that can meet increasingly rigorous requirements. Research and development efforts are likely to focus on enhancing bearing materials, refining manufacturing processes, and optimizing design parameters to further improve performance and reliability in high-speed applications.

Final Thoughts on the Role of Full Complement Bearings in Enhancing Performance in High-Speed Applications:

In closing, it is evident that full complement cylindrical roller radial bearings play a pivotal role in enhancing the performance of machinery operating in high-speed applications. Their unique design features, coupled with their ability to withstand heavy loads and operate at elevated speeds, make them indispensable components in modern industrial machinery. By harnessing the benefits of these bearings, engineers and manufacturers can achieve higher levels of efficiency, reliability, and productivity, ultimately driving innovation and progress in high-speed industries.

In summary, the adoption of full complement bearings represents a paradigm shift in the design and performance of machinery operating in high-speed applications. By maximizing load capacity, minimizing friction, and improving overall efficiency, these bearings play a crucial role in enhancing performance and reliability across various industries. As industries continue to evolve and innovate, the future of full complement bearings holds promising prospects for further advancements and applications in high-speed machinery.

7 FAQs: Common Questions About Cylindrical Roller Radial Bearings/Full Complement

Q1: What are Cylindrical Roller Radial Bearings?

A: Cylindrical roller radial bearings are precision-engineered components designed to facilitate rotational motion while supporting radial loads. They consist of cylindrical rollers held in place by inner and outer rings, providing high radial stiffness and load-carrying capacity. These bearings are commonly used in various industrial applications, including machinery, automotive systems, and power transmission equipment.

Q2: What distinguishes Full Complement Bearings from Standard Bearings?

A: Full complement cylindrical roller radial bearings differ from standard bearings in their design configuration. While standard bearings incorporate a cage or separator to space out rollers, full complement bearings feature a maximum complement of rollers, allowing them to accommodate heavier loads and operate at higher speeds with enhanced stability. The absence of a cage also reduces friction, contributing to improved efficiency and longevity.

Q3: What factors should be considered when selecting Full Complement Bearings for high-speed applications?

A: When choosing full complement cylindrical roller radial bearings for high-speed applications, several factors should be taken into account. These include the bearing's load capacity, speed rating, lubrication requirements, and environmental conditions. It is essential to ensure that the bearings are properly installed, aligned, and maintained to maximize their performance and service life in high-speed environments.

Q4: What are the maintenance requirements for Full Complement Bearings?

A: Proper maintenance is essential to ensure the optimal performance and longevity of full complement bearings. This includes regular inspection for signs of wear or damage, monitoring of lubrication levels, and periodic re-lubrication as needed. Additionally, proper storage and handling practices should be observed to prevent contamination or damage to the bearings before installation.

Q5: Are Full Complement Bearings suitable for use in extreme operating conditions?

A: Full complement cylindrical roller radial bearings are designed to withstand a wide range of operating conditions, including high speeds, heavy loads, and harsh environments. However, it is essential to consider factors such as temperature, moisture, and chemical exposure when selecting bearings for extreme operating conditions. Specialized bearing coatings or materials may be required to ensure optimal performance and durability in such environments.